High Flux Solar Simulator

UF is one of three academic institutions in the United States to have a High Flux solar simulator designed to test high temperature thermal receivers and thermochemical reactors under realistic conditions. It is capable of delivering up to 10 kW of high flux radiation (5000 suns peak) using Xe-arc lamps with a photo-spectrum similar to sunlight. The simulator laboratory is fully equipped with data acquisition and control hardware (temperature, mass flow rates, pressure) residual gas analysis (mass spectroscopy and NDIR) and is fully compatible with a range of reactor geometries and sizes. Beyond testing concentrated solar power receivers and solar thermochemical reactors, this device is well suited for testing materials and/or engineered structures for a range of high temperature applications.

UF is one of three academic institutions in the United States to have a High Flux solar simulator designed to test high temperature thermal receivers and thermochemical reactors under realistic conditions. It is capable of delivering up to 10 kW of high flux radiation (5000 suns peak) using Xe-arc lamps with a photo-spectrum similar to sunlight. The simulator laboratory is fully equipped with data acquisition and control hardware (temperature, mass flow rates, pressure) residual gas analysis (mass spectroscopy and NDIR) and is fully compatible with a range of reactor geometries and sizes. Beyond testing concentrated solar power receivers and solar thermochemical reactors, this device is well suited for testing materials and/or engineered structures for a range of high temperature applications.

High Temperature TGA/DSC

High temperature TGA/DSC (Mettler Toledo, TGA/DSC 2 HT) capable of studying reactions up to 1600 °C. It is coupled with a residual gas analyzer (Stanford Research Systems, QMS100) and in situ O2 sensor (Econox CarboProbe DS). Includes 5 reactive gas ports and 3 mass flow controllers (2 electronic and 1 rotometer).

High temperature TGA/DSC (Mettler Toledo, TGA/DSC 2 HT) capable of studying reactions up to 1600 °C. It is coupled with a residual gas analyzer (Stanford Research Systems, QMS100) and in situ O2 sensor (Econox CarboProbe DS). Includes 5 reactive gas ports and 3 mass flow controllers (2 electronic and 1 rotometer).

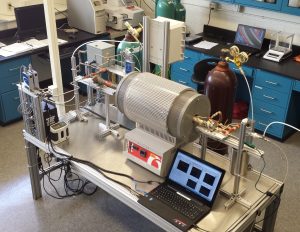

Tubular Reactor for Studying Heterogeneous Reactions

An experimental reactor capable of achieving temperatures up to 1600°C. The reactor utilizes a Carbolite STF 16/180 high temperature tube furnace to accurately control the temperature of the reaction tube and a Stanford Research Systems QMS 100 Series gas analyzer to quantify the product species. Three MKS gas mass flow controllers are used to accurately deliver specific gas concentrations to the reaction tube and a custom-built steam furnace coupled with a Bronkhorst liquid flow controller allows for delivery of steam for studying oxidation and corrosion behavior of metals and oxides. A sub-ambient pressure controller downstream of the system enables pressure control from vacuum conditions to ambient pressures.

An experimental reactor capable of achieving temperatures up to 1600°C. The reactor utilizes a Carbolite STF 16/180 high temperature tube furnace to accurately control the temperature of the reaction tube and a Stanford Research Systems QMS 100 Series gas analyzer to quantify the product species. Three MKS gas mass flow controllers are used to accurately deliver specific gas concentrations to the reaction tube and a custom-built steam furnace coupled with a Bronkhorst liquid flow controller allows for delivery of steam for studying oxidation and corrosion behavior of metals and oxides. A sub-ambient pressure controller downstream of the system enables pressure control from vacuum conditions to ambient pressures.

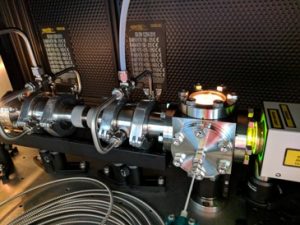

Laser Based Heating System with In Operando Raman Spectroscopy

Main component of the system is the CO2 laser (Kern Technologies, KT200) having 10.6 um wavelength and 200 W maximum power. Two Mass flow controllers (MKS Instruments, GE50A) are utilized to mix various reactive gases.

Raman system is composed of Raman laser (Laser Quantum, Ventus 532) with 532 nm wavelength and 100 mW maximum power, Raman spectrometer (Horiba Scientific, iHR 550) with 550 mm focal length and three different gratings (150 gr/mm, 600 gr/mm, 1800 gr/mm), CCD camera (Horiba Scientific, Syncerity) with the resolution of 1024 x 256 – 26um pixel size and the Raman probe (Horiba Scientific, Superhead 06/640).

Sintering Furnace and Pellet Press

Sintering furnace (Carbolite RHF 16/8 1600C Box Furnace) capable of acheiving 1600 °C and pellet press (Carver 12 ton hydraulic press) for sample prep and material synthesis/calcination.