Students

Tommy Smola

Summary

Hydrogen is quickly becoming a ubiquitous resource in America’s diverse production economy. From being a fuel source for certain vehicles to the production of steel, electric vehicles, and fertilizers, the need for hydrogen is currently deeply ingrained in many industrial processes. Unfortunately, the currently mainstream methods for the large-scale production of hydrogen leaves a significant carbon footprint. To combat this, the department of energy has placed an emphasis on alternative methods for hydrogen production through funding numerous projects to accomplish that goal.

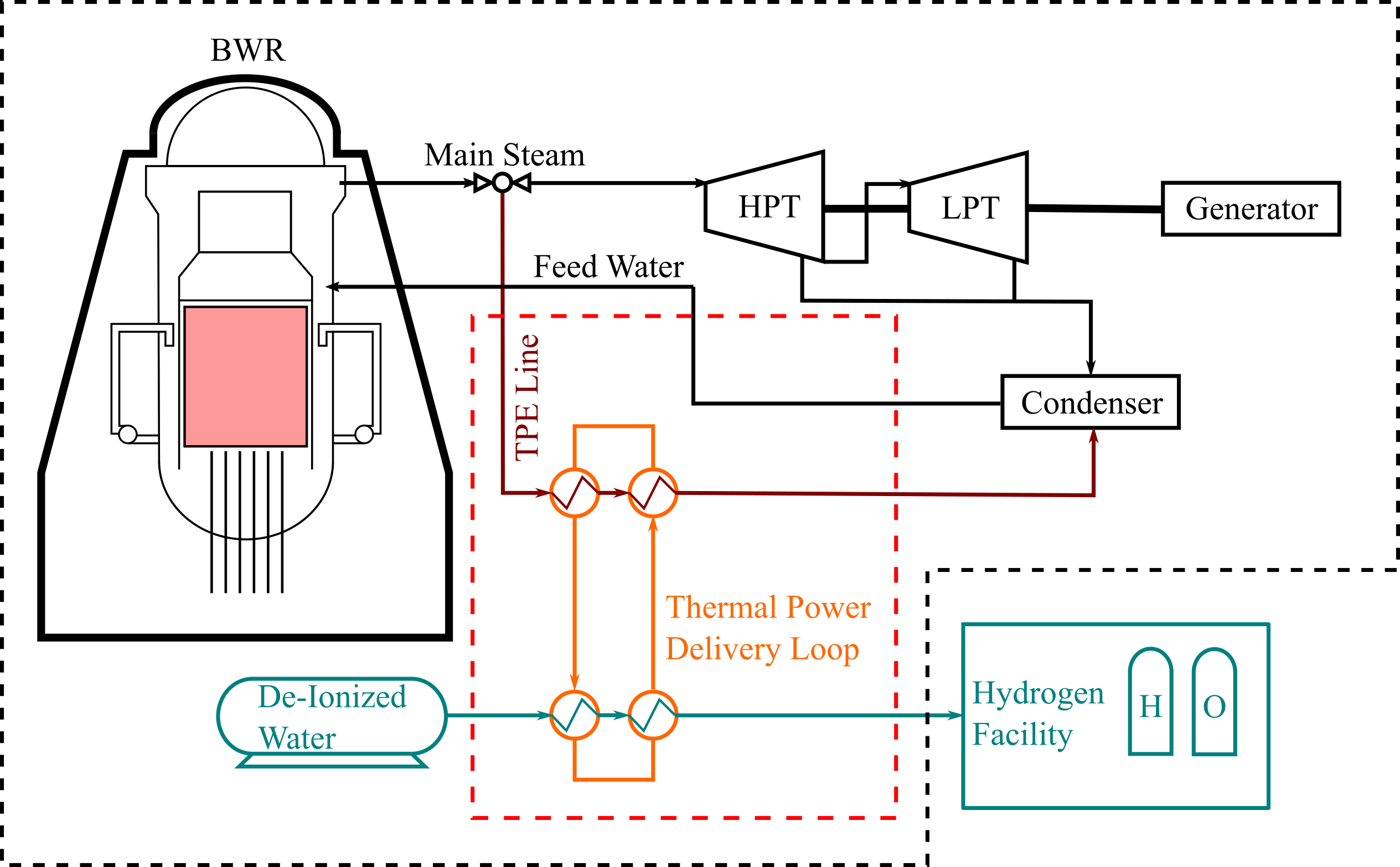

GSE Systems, Idaho National Laboratory, and the University of Florida have begun a collaborative effort to develop a path which takes advantage of the energy source that has the lowest feasible carbon footprint: nuclear reactors. By combining the robust heat transfer system associated with nuclear reactors with a heat efficient industrial hydrolysis plant, large scale hydrogen production will be made possible in tandem with safe and reliable baseline energy production.

To start the process of mending these two systems, software currently used to model the steam delivery system of pressurized water reactors (PWRs) and Boiling Water Reactors (BWRs) is being modified to allow for the introduction of a hydrogen production facility. By updating the software to balance the heat load that would be introduced by including a hydrolysis plant, we will have a better understanding of what will be required for its integration. This work will lead to a long-term collaborative effort to make hydrogen production much more robust, efficient, and environmentally friendly while also taking advantage of an existing and reliable infrastructure.