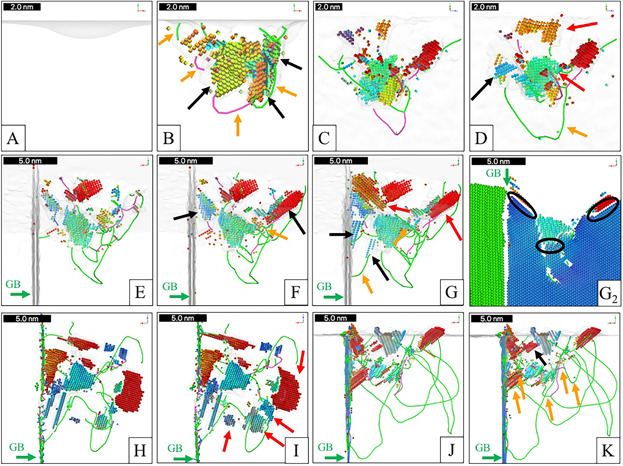

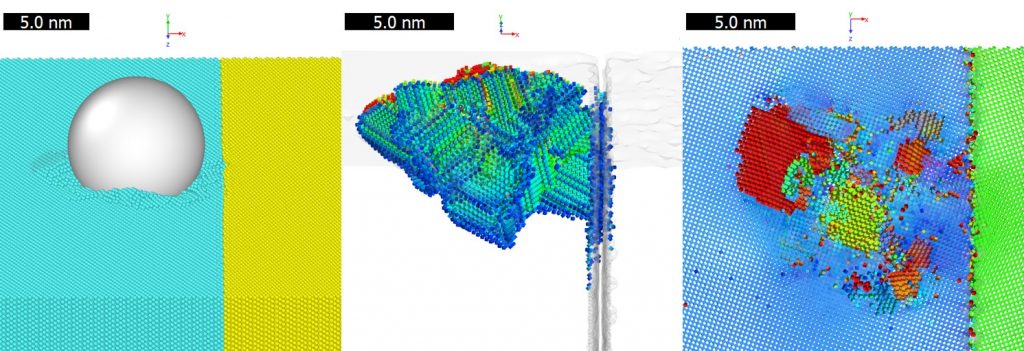

- Examine Interface Effects

The mechanical behavior of materials at sub-micron scales differs drastically from that at the macroscale, due to the high surface-to-volume ratio. In order to understand the behavior of materials we introduce a new grain boundary energy (Φgb) that depends on the plastic strain at the grain boundary (GB) and is therefore a measure of the energy change that the grain boundary undergoes during plastic deformation, rather than the thermodynamics (or static) energy (γgb ) that is commonly used to characterize GBs. Although the materials science community has not explicitly introduced such mechanically induced GB energy terms, their existence can be alluded to by in situ transmission electron microscopy (TEM) studies that examine dislocation-grain boundary interactions and capture dislocation absorption/emission/transmission. In our work we perform molecular dynamics simulations, as it is possible to track the dislocation formation and evolution and selectively vary the grain boundary structure. We therefore are able to measure Φgb for different materials systems. In this figure MD indentation was performed near a grain boundary allowing for dislocation and twin formation and accumulation at the grain boundary. Non-defect atoms are kept white.