The Role of Grain Boundary Structure and Chemistry in Materials

Scope

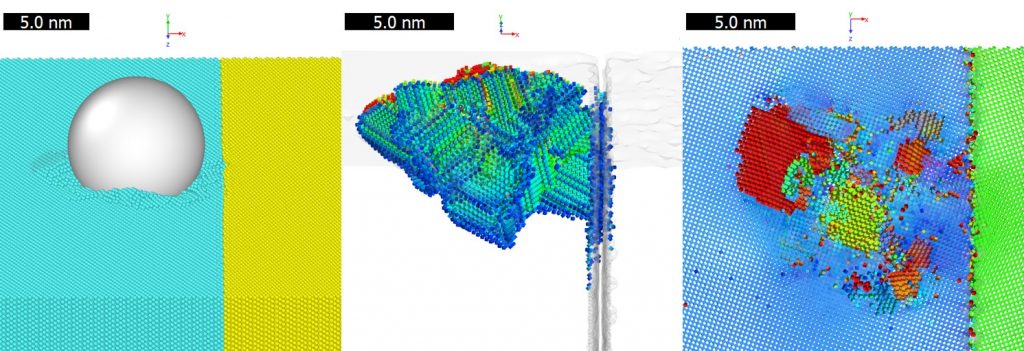

This research builds on the hypothesis that the presence of grain boundaries during deformation can be captured by mechanically induced interface energies (Fgb). Fgb depends on the plastic strain at the grain boundary (GB) and is therefore a measure of the energy change that the grain boundary undergoes during plastic deformation, rather than the thermodynamics (or static) energy (ggb) that is commonly used to characterize GBs. Although the materials science community has not explicitly introduced such mechanically induced GB energy terms, their existence can be alluded to by in situ transmission electron microscopy (TEM) studies that examine dislocation-grain boundary interactions and capture dislocation absorption/emission/transmission. Molecular dynamics simulations have also recognized that ggb on its own cannot characterize the GB strength, and the concept of an energy barrier was introduced, which however, cannot capture continuous GB deformation, but only the first slip.

Fgb can be incorporated within the continuum theory of gradient plasticity, allowing the prediction of the critical stress at which GBs begin deforming plastically (GB yield stress/sgb). It is therefore possible to measure Fgb and understand its origin by performing experiments and simulations that can track defect-GB interactions and provide the strain state of the material.

Summary of published articles:

- Interpreting slip transmission through mechanically induced interface energies: a Fe–3% Si case study, Aifantis, K.E., Deng, H., Shibata, H. et al. J Mater Sci (2019) 54: 1831.

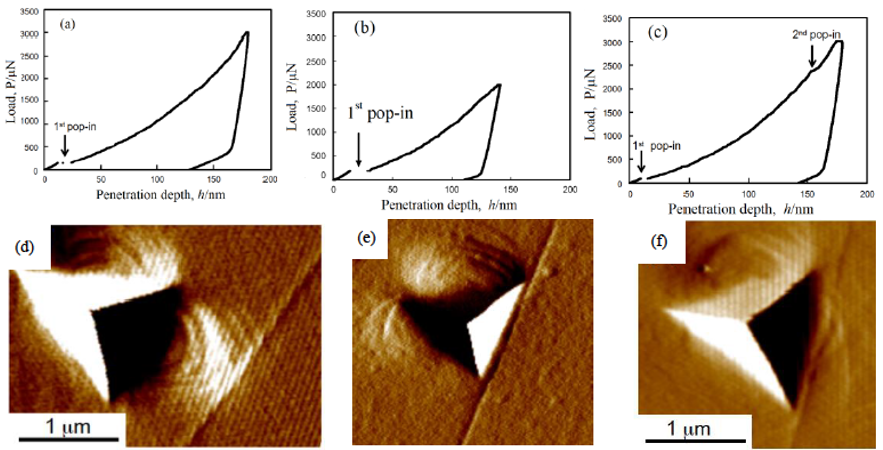

As a first step to confirming the “existence” of Fgb nanoindentation experiments were used since it has been shown that indenting in close proximity to GBs allows for second pop-ins to be obtained in the load-displacement curve, which can be assumed to indicate slip transmission, i.e. GB yielding. A brief summary is provided below but detailed information can be found in our recent published paper [Aifantis, K.E., Deng, H., Shibata, H. et al. J Mater Sci (2019) 54: 1831]. By indenting near GBs of Fe-3wt% Si and performing scanning probe microscopy (SPM) it was possible to verify that indeed slip transmission was present when a secondary pop-in took place, as seen in Fig. 1.

From the load-displacement curves it is possible to obtain an approximation through Tabor’s rule of the stress present during the second pop-in, which corresponds to the GB yield stress, sgb, which is predicted by gradient plasticity as

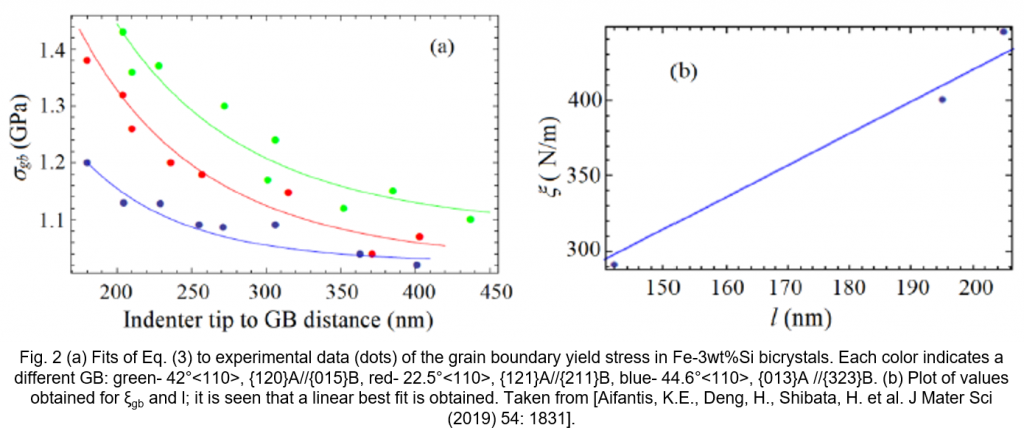

d is a fixed length during deformation, b is the hardening modulus, l is the internal length which is a parameter indicating a critical length scale, and xgb is an interface parameter directly related with Fgb. Fitting Eq. (1) to the experimentally obtained points for sgb against the GB-indenter distance (d) showed that indeed introduction of mechanical energy terms is capable of capturing the resistance of GBs to deformation, since an excellent fit was obtained (Fig. 2). Comparing the ξgb values for the various GBs examined did not indicate a correlation with misorientation, however, a dependence with the grain boundary plane was noted in [Aifantis, K.E., Deng, H., Shibata, H. et al. J Mater Sci (2019) 54: 1831], which is similar to the dependence of the thermodynamic grain boundary energy on misorientation and GB plane.

Fig. 1. Representative nanoindentation load-depth curves and SPM images obtained when the grain boundary had a 42.0°<100> misorientation: (a) indentation in the grain interior ; (b) indentation near the GB with the maximum load being 2 mN ; and (c) indentation near the GB with the maximum load being 3 mN ; (d) SPM image of indent in grain interior, taken after the curve shown in (a) ; (e) SPM image of surface after the indentation curve shown in (b) ; (f) SPM image of the surface after the indentation show in (c). It is seen that for the case that a second pop-in occurs slip is transmitted to the neighboring grain. Taken from [Aifantis, K.E., Deng, H., Shibata, H. et al. J Mater Sci (2019) 54: 1831]. Arrows indicate slip transmission.

- The Formation and Evolution of Defects in Nanocrystalline Fe During Indentation: The Role of Twins in Pop‐Ins, Kuhr, B. R. and Aifantis, K. E. (2019), Phys. Status Solidi B, 256: 1800370

Nanoindentation is a most common experimental tool used for obtaining information on the mechanical behavior of materials. This is done by qualitatively relating the occurrence of pop‐ins (in the load–displacement plots) to microstructural changes such as dislocation formation, fracture of surface oxides, or slip transmission. The present study takes a first approach in directly verifying the micro‐plasticity processes that give rise to such pop‐ins by performing molecular dynamics indentation simulations in BCC Fe‐nanocrystals with a Σ5 symmetric tilt boundary. The simulations allow to track the material behavior throughout the indentation process, and illustrate that each pop‐in is related to twin formation, twin growth, de‐twinning, dislocation nucleation and glide, or dislocation–grain boundary interactions. For the particular Σ5 boundary considered, it is found that the pop‐ins are most closely associated with twin formation. Although pop‐ins have been related to dislocation nucleation, a direct correlation between twinning and pop‐ins has not been shown before. Adding C segregants to the Fe sample, reduced the formation of twins after initial yielding, and allowed for dislocation activity to become the more dominant deformation mechanism.

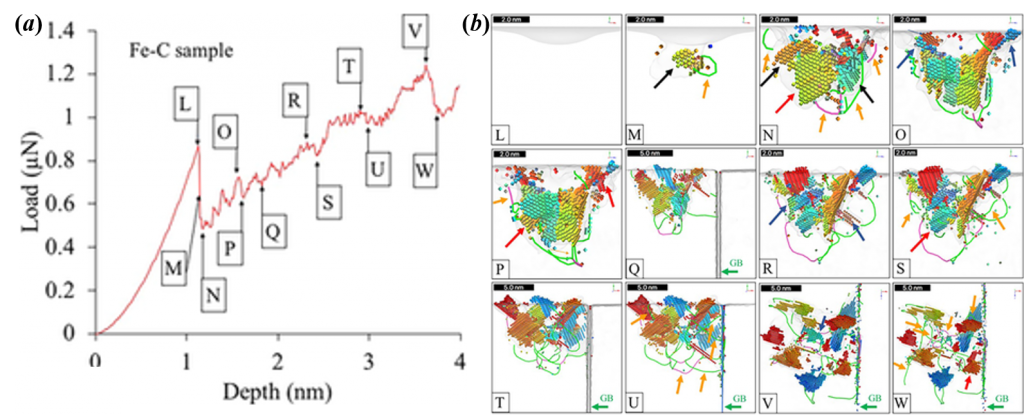

Fig. 3 (a) Load–displacement curves for indentation of the Fe‐C sample. (b) Defect formation during pop‐ins in the Fe‐C sample. Letters indicate the position on the load displacement curve in (a). Red, black, blue, and orange arrows indicate twin growth, new twins, de‐twinning, and new dislocations, respectively.

- Interpreting the inverse Hall-Petch relationship and capturing segregation hardening by measuring the grain boundary yield stress through MD indentation, Bryan R. Kuhr, Katerina E. Aifantis, Materials Science and Engineering: A, Volume 745, 2019, Pages 107-114, ISSN 0921-5093

The inverse Hall-Petch relationship, which occurs below a critical grain size, is attributed to the high interface to volume ratio that characterizes nanocrystalline metals. This has led some theoretical models to treat nanocrystals as composite materials in which the grains and grain boundaries behave as two separate phases, which follow their own yield behavior. The present study provides first estimates of a grain boundary yield stress, by employing molecular dynamics indentation. The case system considered was that of nanocrystalline Fe with a Σ5 symmetric boundary and indentations were performed either in the grain interior or on the grain boundary illustrating that grain boundaries yield at less than half the stress that grains do. This can interpret the inverse Hall-Petch relationship, since as the grain size decreases below a critical value, the grain boundary thickness is not negligible and its low yield stress dominates the material behavior. To stabilize the boundary from migration/sliding and capture the effect of segregation the simulations were repeated when 0.008% C impurities were added into the sample. This low C content resulted in a higher grain boundary yield stress, without however increasing the grain interior yield stress, illustrating the sensitivity of grain boundaries to segregant atoms. In addition to shear strain maps, a new visual representation was done by using different colors to indicate the orientation of atoms during indentation, as would be done experimentally with electron backscatter diffraction. It was therefore possible to reveal the occurrence of twinning, in addition to dislocation nucleation.

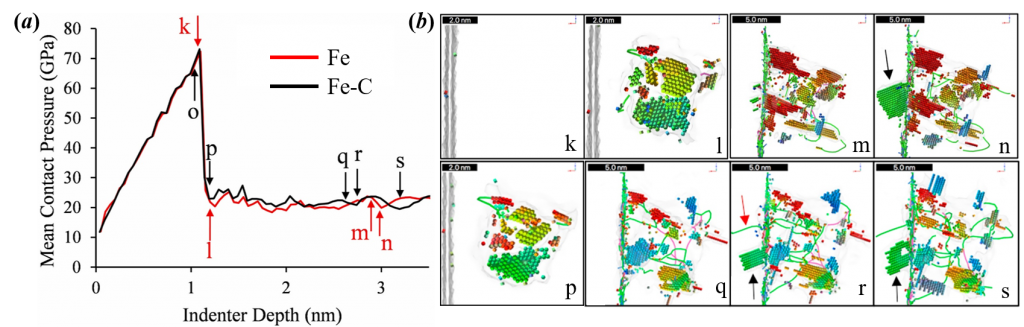

Fig. 4. (a) Hardness –displacement curve near the grain boundary in Fe bicrystals with and without C; (b) corresponding defect and dislocation formation.

- Effect of Processing on Nix-Gao Bilinear Indentation Results Obtained for High Purity Iron, Soman, P., Herbert, E., Aifantis, K., & Hackney, S. (2018), MRS Advances, 3(8-9), 477-486.

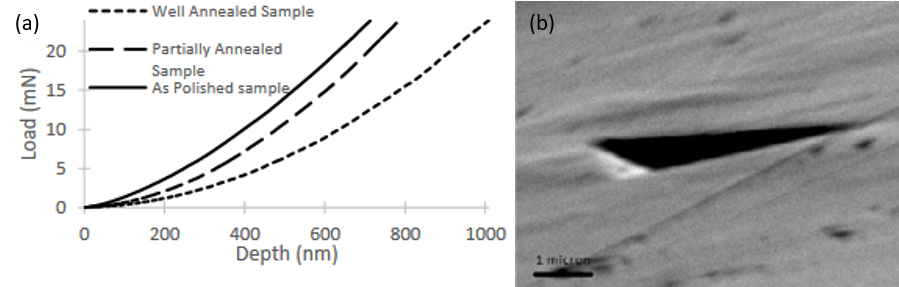

Instrumented indentation of a high purity Fe surface with unresolved surface deformation due to mechanical polishing is compared to the same grain surface annealed at increasing time and temperature. The differences in indentation size effect behavior with annealing are correlated with hardness and electron backscatter diffraction measurements as independent measures of surface layer deformation. It is found that the Nix Gao plot evolves from non-linear (bilinear) towards the predicted linear relationship as the surface deformation is removed. The experimental observations are rationalized by inclusion of a depth dependent, polishing induced forest dislocation density within the Nix-Gao model.

Fig. 5 (a) Representative P-h curves, (b) SEM indent image tilted to ~80 degrees.