With the advances in electric vehicles and renewable energies new focus is currently being given world wide on energy storage. We develop design criteria for predicting the most promising nanostructured anodes for Li-ion and Na-ion batteries. We started working on these topics since 2001, and applied the first theoretical models for capturing stress evolution in Sn/Si nanocomposites.

Lithium-ion Batteries

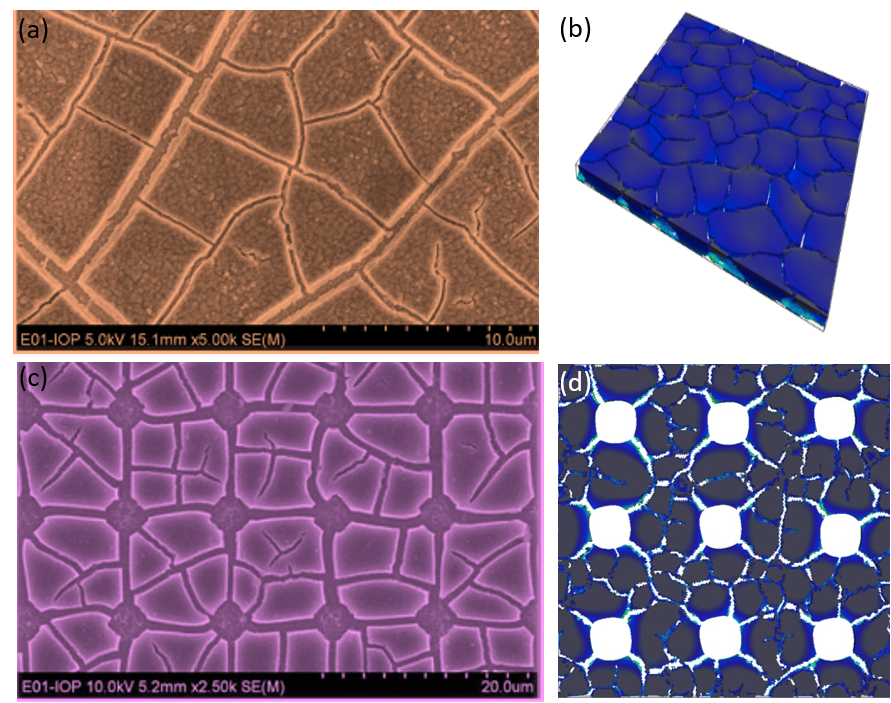

Si is the most promising anode for lithium batteries as it allows for a capacity of over 4000 mAh/g. During electrochemical cycling, however, a continuous capacity decay occurs due to fracture which results from the 400% volume changes that Si undergoes upon the Li insertion and de-insertion process, as seen in Figure 1a. We focus on developing theoretical models that can capture and predict this fracture which in turn can give design criteria for Si nanocomposite anodes that can withstand fracture. Our published results show excellent agreement between our model and experimental results for fracture on a Si thin film (Figure 1).

Sodium-ion Batteries

Sodium-ion batteries have been receiving increased attention as alternatives to Li-ion batteries in grid storage systems due to the abundance and lower cost of Na. Despite the great progress in developing new electrode materials with a high capacity, they lack long term electrochemical stability and therefore their practical application remains a challenge. Na-ion and Li-ion batteries display many similarities, the most common being that Li compounds that are promising electrodes for Li-ion batteries can be used in Na-ion batteries as well. Since the radius of Na is larger than Li it would be expected that damage in Na-ion batteries is more severe than in Li-ion, however, this has not been explored. Our studies are the first to reveal an in depth analysis of the mechanical stability in electrodes used in Na-ion cells, such as Sn (Figure 2) and TiS 2 (Figure 3).