Centrifuges

- 1.5-meter radius: functional limit of 90 g’s, 12.5 g-Tons payload capacity and 6.5 cu. ft. model

- 1-meter radius: functional limit of 90 g’s, small payload capacity and 1 cu. ft. model

Experimental Resources

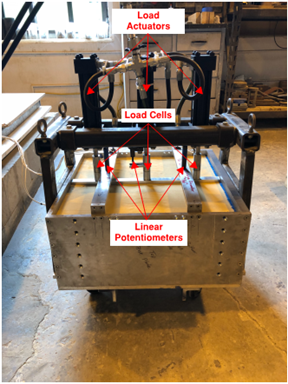

Model Containers and Sensing. Multiple model containers and reaction frames are available experiments. Each container and frame has been designed to withstand the high gravity forces with capacity/demand of 2. An array of sensors and hardware are available for measuring load, displacement, soil pressure (internal and on surface), pore water pressure, temperature, and strain.

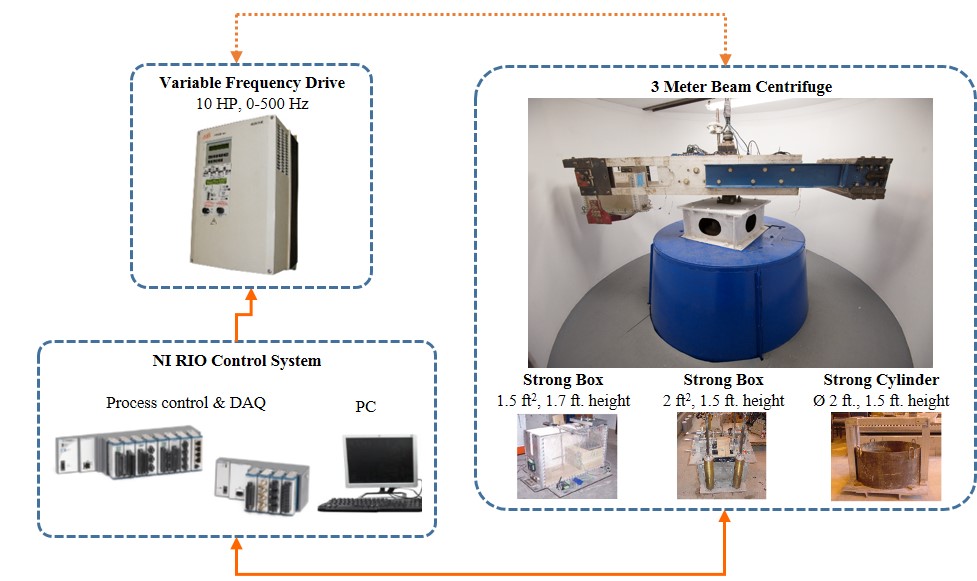

Real-Time Analysis and Control. The centrifuge is equipped with a NI c-RIO that is programmed to control the  Variable Frequency Drive (VFD) that enables the motor to rotate and spin the centrifuge at RPMs to achieve the desired g-level for testing. All actuation and measurements are monitored in real time through custom software. Data is collected and stored on an dedicated computer with backup to long-term storage.

Variable Frequency Drive (VFD) that enables the motor to rotate and spin the centrifuge at RPMs to achieve the desired g-level for testing. All actuation and measurements are monitored in real time through custom software. Data is collected and stored on an dedicated computer with backup to long-term storage.

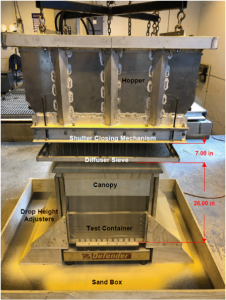

Staging and Placement of Model Experiments. All stages of a model experiment can be handled in the laboratory. Affiliated fabrication shops are used for container construction. Model assembly takes place outside the centrifuge. A large pluviator is used for placement of model sand and particulates to achieve medium dense to very dense states. The completed model is placed onto the carriage arm using a cantilever crane and hoist.

Data Archival and Curation. The laboratory has access to the UF Data Center, which houses a high performance computing center and long-term replicated storage. All hardware connected via a 10 Gbps Science DMZ network architecture, which is dedicated high-volume data transfer network exclusively operated to support experimental and computational research. Data archival can be fully automated. The data acquisition system saves data to local storage and continuously backs up data to long-term replicated storage at the data center through an ownCloud platform, which is a Dropbox-like interface based on the Globus GridFTP platform.

Live Video Monitoring. Multiple options are available for monitoring and recording the model in flight and during each experiment. Some test containers use transparent sidewalls for observation of shear failure lines in the models, which can be observed using a video camera and live feed to the control room. A HD video camera is also available for placement above the model for observation during each test. Outside observers can participate in the experiment through remote access to shared screens of the real-time data collection and model observations.

Live Video Monitoring. Multiple options are available for monitoring and recording the model in flight and during each experiment. Some test containers use transparent sidewalls for observation of shear failure lines in the models, which can be observed using a video camera and live feed to the control room. A HD video camera is also available for placement above the model for observation during each test. Outside observers can participate in the experiment through remote access to shared screens of the real-time data collection and model observations.

Security and Safety. In addition to the data archival steps that guarantee security, the system is on its own isolated network. Furthermore, internal safety measures are followed guarantee non-hazardous centrifuge operations. Frequently updated SOPs are available for all users, lock out/tag out procedures are followed, emergency shut off buttons are at the lab entry points and in the control room, safety lock is on the centrifuge access door, and audio and visual warning is used to indicate activation of power to the centrifuge.