Research

Focus Area 1

Shape Memory Alloys – Synthesis and Characterization

This is an effort on basic research, focused on the development and characterization of a novel quaternary precipitation hardened shape memory alloy with higher transformation temperature and improved strength. Dr. Gallo is responsible for the design, synthesis, processing, and characterization of the new system, researching under Michele Manuel, Ph.D., a MSE faculty member and department chair, and in collaboration with Honggyu Kim, Ph.D., assistant professor of materials science and engineering. Dr. Kim is the PI and Dr. Manuel is the co-PI of a National Science Foundation grant to accurately correlate the characteristics and properties of nano-sized precipitates to shape memory performance.

It is an ongoing project and so far, high-angle annular dark-field (HAADF) nanobeam electron diffraction (NBED) and 4D-STEM have been used to characterize the matrix, the co-precipitation of Heusler and H-phase, identifying the locations and magnitude of the high strain fields surrounding the precipitates for one alloy composition and heat treatment. In-situ STEM is being set up for the understanding of the synergic effect of both precipitates and their strain fields in the martensitic transformation.

In parallel with the TEM characterization, thermal analysis and mechanical properties of the studied systems are being investigated in our Materials Design ad Prototyping Laboratory (MDPL).

Focus Area 2

Nondestructive Techniques for Weld Inspection

The research focused on demonstrating and implementing infrared thermography non-destructive technique (IR-TNDT) methods in-service for inspecting aluminum (Al) and steel welds in complex structures. The study was applied to in-shop and mock in-field conditions. After a thorough literature review, this report presents the qualification of defect manufacturing procedures in the selected base materials, followed by sample preparation methods before infrared (IR) imaging. The work investigates the utility of the FLIR C5 and T620 cameras to produce a reliable and repeatable inspection of weld defects. The effect of applying protective coatings to the steel weld joint surface and a surface finish method applied to Al weld joints were addressed. The results illustrate that IR-TNDT is a promising non-destructive technique to identify surface-breaking defects in weld joints. However, proper defect identification is very sensitive to surface features. Quantitative destructive analysis was performed on weld joints to correlate defect geometry and location in the IR images. The FLIR T620 camera provided higher contrast and resolution imaging of surface-breaking defects than the FLIR C5 camera. It is recommended that IR-TNDT for steel and Al weld defect characterization be used concurrently with other non-destructive testing (NDT) techniques.

Figure shows visual (top) and IR-TNDT (bottom) images at 100°C of the steel plate-to-plate samples with the surface-breaking drill hole mimicking an on-site defect. A linear temperature profile along the weld line plotted from the IR images of the uncoated and coated samples. A peak in temperature at the defect center can be perceived in the uncoated, one layer of Zinc-It®, and three layers of Zinc-It® samples for different steel weld geometries.

This research study was supported by FDOT and the final report is yet to be published.

Failure Analysis and Environmentally Assisted Embrittling Mechanisms in Structural Materials

Dr. Gallo’s D.Sc. dissertation was focused on the manipulation of grain boundary character distribution through thermomechanical processing via cold-rolling of thin sheets of Ni-based superalloy 718. The effect of the resulting microstructure in the susceptibility of the alloy to oxidation assisted intergranular cracking (OAIC) embrittling phenomenon at or above 650°C, was addressed, based in diffusion theory and fractography analysis.

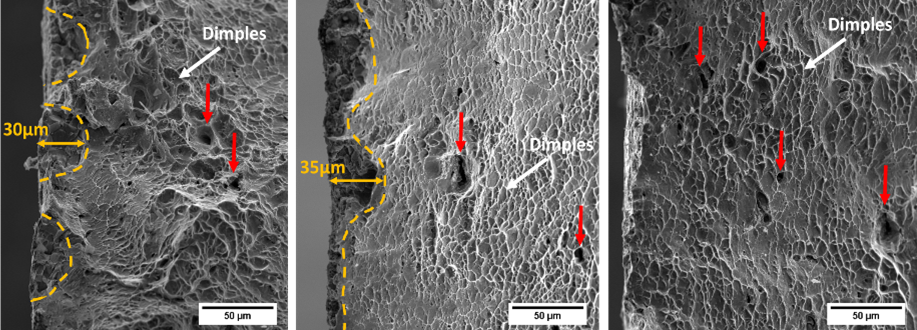

Figure below shows the fracture surface of tensile specimens subjected to tests at 650°C, after being thermomechanically processed according to three different routes. Results, compared to oxygen diffusion calculations, demonstrated that the route that resulted in the increased length fraction of special (Σ3n) grain boundaries were more resistant to oxygen penetration, thus, to the OAIC embrittling mechanism, showing a 100% ductile fracture.

Learn more at: https://doi.org/10.1016/j.msea.2021.141922 and at: https://doi.org/10.1016/j.jmrt.2019.12.011

Additionally, Dr. Gallo works in a collaborative project with the Federal University of Rio de Janeiro, Brazil, which focus on failure analysis of centrifugally cast Nb-modified HP austenitic stainless steels tubes used for hydrogen production in steam reformer furnaces, after in-service aging at temperatures above 900°C. Unexpected operational problems caused severe overheating, also called “short-time temperature surges”, which led tubes to premature failure through the formation of large longitudinal cracks. However, one of the main findings of the study was that the tubes that underwent the temperature surge without cracking showed a remaining safe life of more than 5 years. This was estimated based on creep tests and microstructural evolution analysis. It was found that the Nb carbides reprecipitation and refinement due to the thermal cycle imposed by the surge, resulted in an increase in overall creep resistance of the steel. Ultimately, their Brazilian group’s study resulted in significant savings for the National Oil & Gas industry, avoiding unnecessary replacement of uncracked tubes, which was a common practice, besides reducing cost with maintenance and plant shutdowns.

Learn more at: https://doi.org/10.1016/j.jmrt.2022.11.130