Research

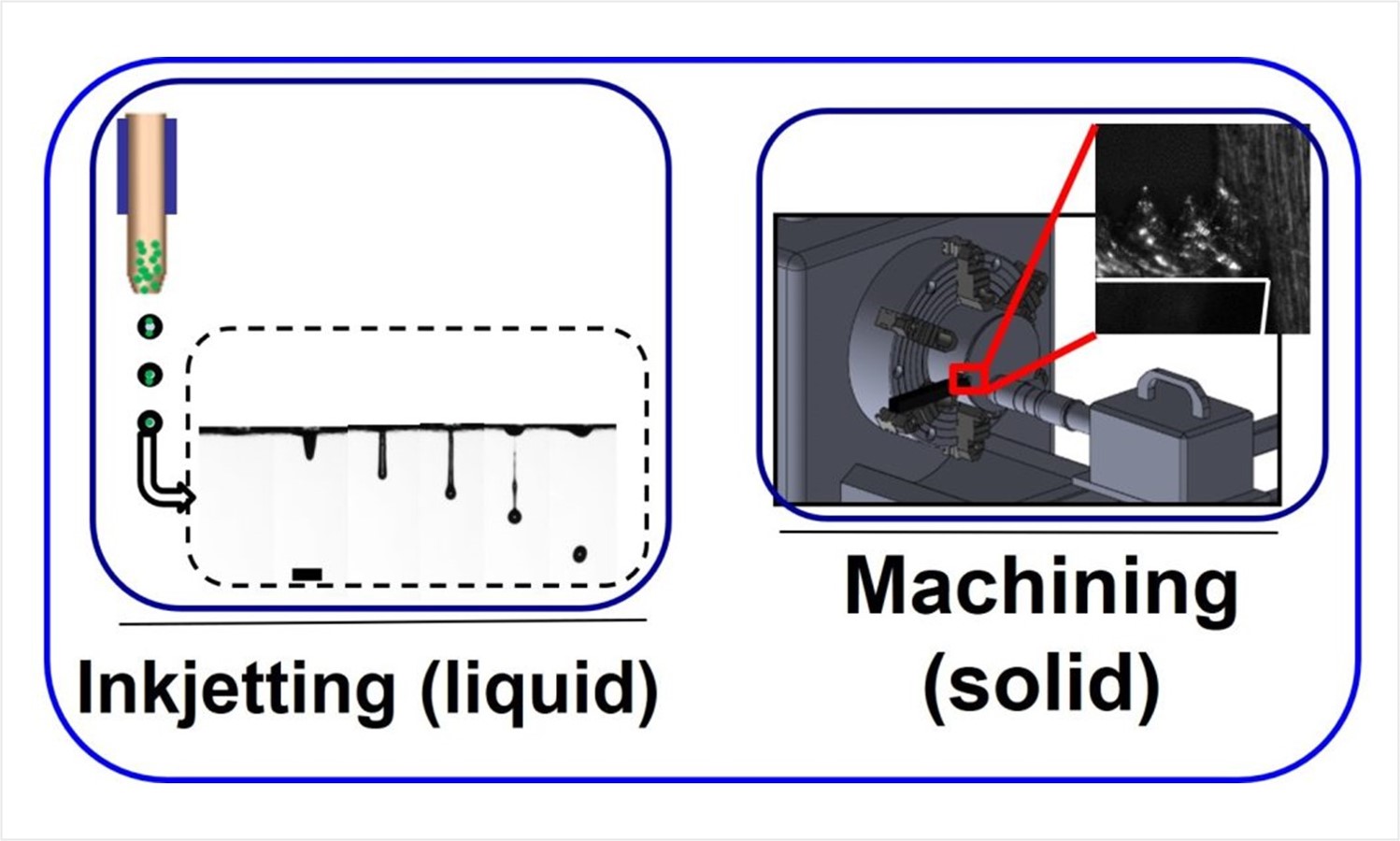

Study of dynamic material behavior using jetting and machining

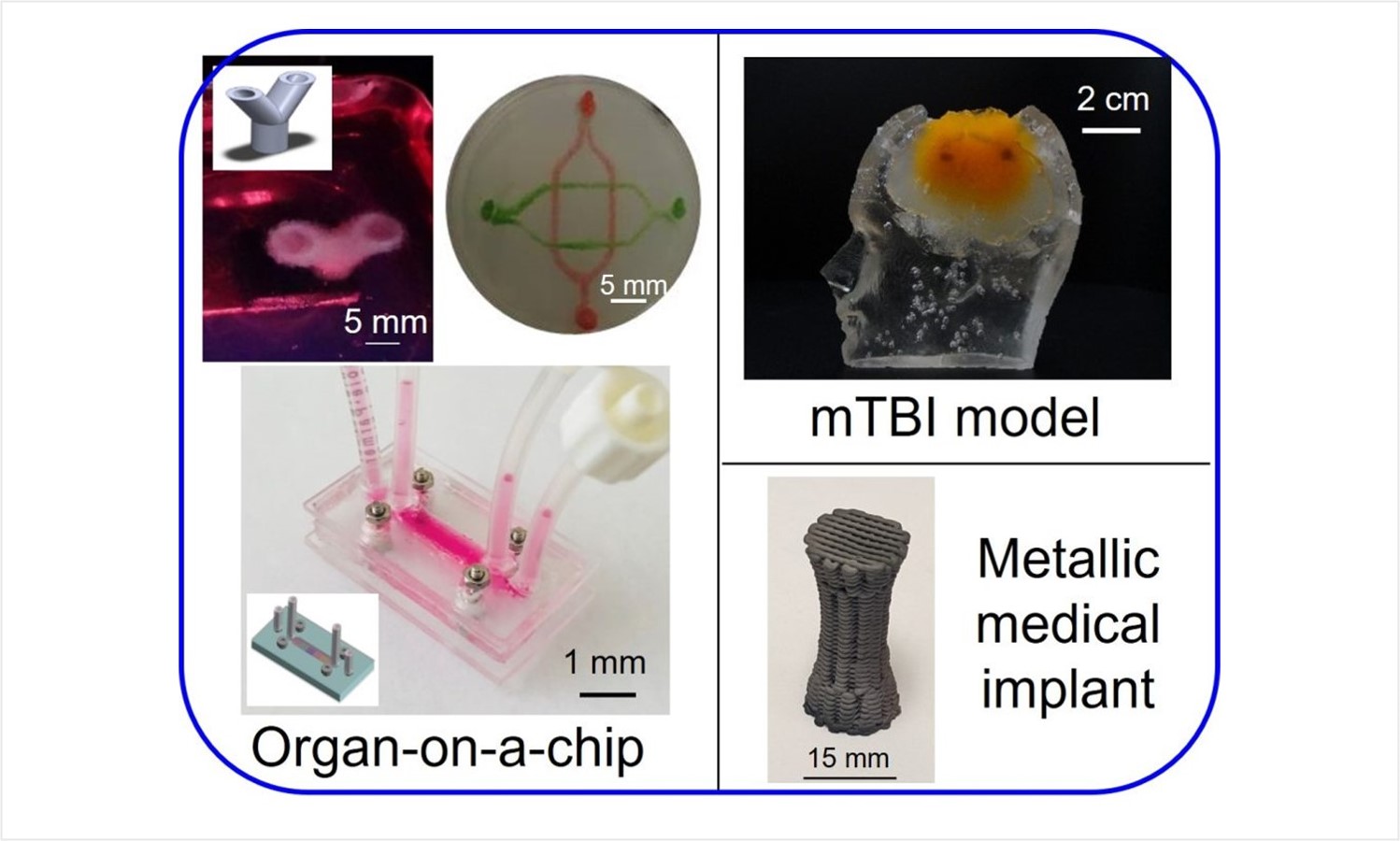

Different from using manufacturing as an approach to transforming raw materials into final products, we aim to use manufacturing to create complex dynamic loading conditions to study the dynamic material behavior of materials as well as investigate process-induced damage such as living cell injury or defect structures such as excessive grain growth. Specifically, we use inkjetting and laser-induced forward transfer to study the droplet formation behavior of complex fluids via the jetting and pinch-off process (with a shear strain rate up to 105/s) and machining to study the dynamic material behavior of solids via the chip formation process (with a strain rate up to 108/s).

Select research:

⚬ Understand the chip formation mechanism when machining ductile and brittle materials

⚬ Understand the printability of cell-laden viscoelastic bioinks

⚬ Investigate jetting conditions and material rheological properties on droplet formation

⚬ Understand and model the printing-induced cell injury

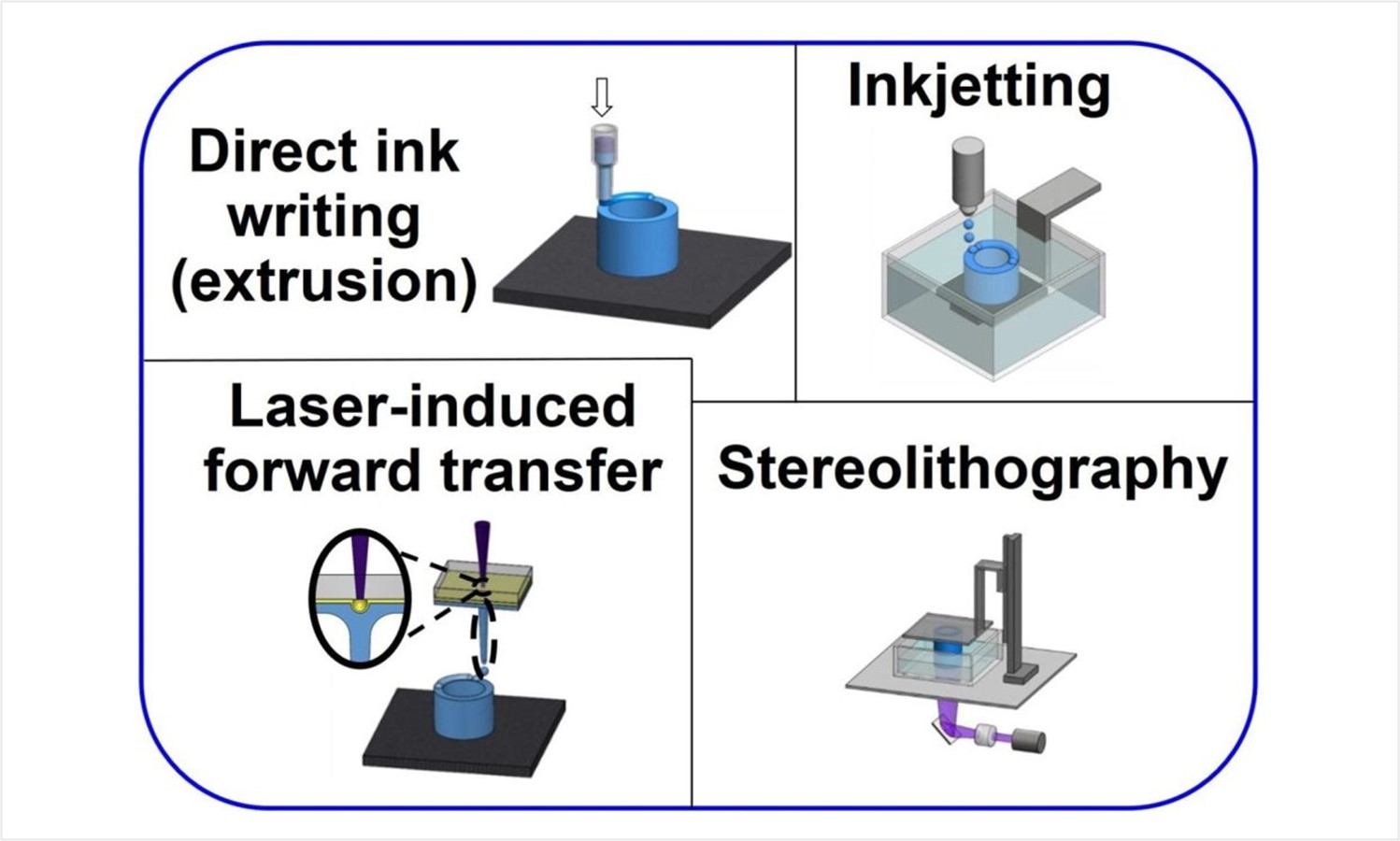

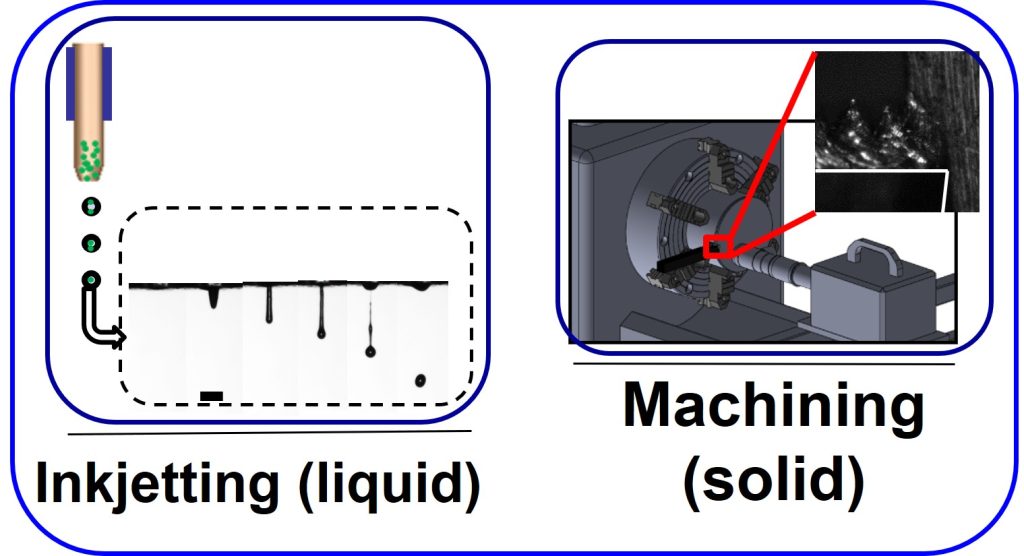

Three-dimensional (3D) printing of biological and engineering structures from difficult-to-print materials using inkjetting, extrusion, laser-induced forward transfer, and stereolithography

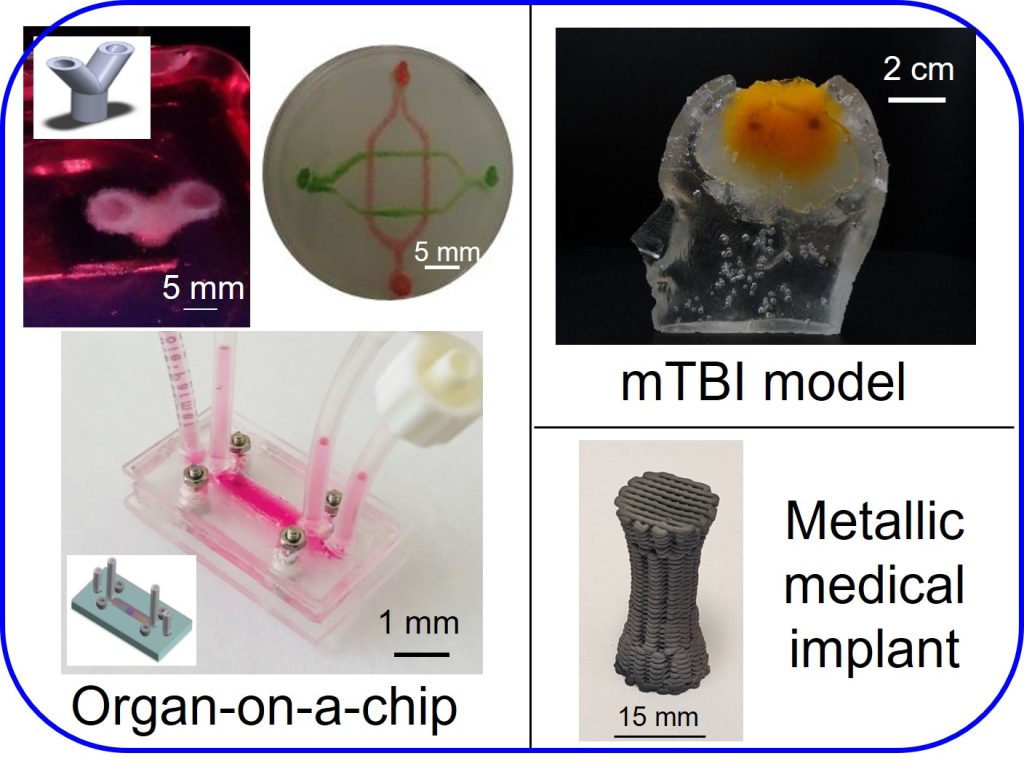

Our additive manufacturing/printing-related activities are to layer-by-layer scaffold-free fabricate human tissues and 3D engineering structures using jet-based (laser- and inkjet-based), filament-based (extrusion), and light-based (stereolithography) direct-write technologies. Instead of being a printing technology user, we strive to be a technology provider, which has been corroborated by our thirteen printing-related patents during the past several years.

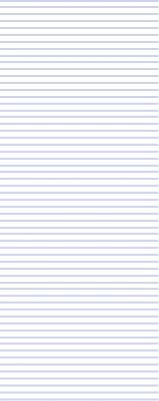

Design and fabrication of microphysiological & engineered living systems and combinatorial materials

Herein we strive to fabricate living cell-based 3D biological constructs using applicable printing and molecular engineering technologies. With cell/organ printing as the most significant application venue, maskless printing is a revolutionary advance to print arbitrary cell patterns as well as to create heterogeneous 3D living constructs cell by cell. It is noted that the same approach can be readily applied to the printing of combinatorial materials as well. Most importantly, bioprinting or cell direct writing provides a promising solution to the challenge of organ donor shortage by fabricating vascularized, innervated thick tissue constructs to mimic the cellular organization of native organs, resulting in what is known as organ printing. Some envisioned products include microphysiological systems (MPS) and soft robots in addition to engineered living materials (ELM) and protocells/prototissues.

Highlighted Research Articles

Recent representative papers

R-1. Huang, Y., Leu. M.C., Mazumder, J., and Donmez, A., “Additive Manufacturing: Current State, Future Potential, Gaps and Needs, and Recommendations,” ASME J. of Manufacturing Sci. and Eng., Vol. 137(1), pp. 014001-1-10, 2015.

R-2. Huang, Y., and Schmid, S.R., “Additive Manufacturing for Health: State of the Art, Gaps and Needs, and Recommendations,” ASME Journal of Manufacturing Science and Engineering, Vol. 140(9), pp. 094001-1-11, 2018.

R-3. Chen, Y., Gao, Z., Hoo, S.A., Tipnis, V., Wang, R., Mitevski, I., Hitchcock, D., Simmons, K.L., Sun, Y., Sarntinoranont, M., Huang, Y., “Sequential Dual Alignments Introduce Synergistic Effect on Hexagonal Boron Nitride Platelets for Superior Thermal Performance,” Advanced Materials, Vol.36(25), p. 2314097, 2024.

R-4. Sole-Gras, M., Ren, B., Ryder, B.J., Ge, J., Huang, J., Chai, W., Yin, J., Fuchs, G.E., Wang, G., Jiang, X., Huang, Y., “Vapor-Induced Phase Separation-Enabled Versatile Direct Ink Writing,” Nature Communications, Vol. 15, p. 3058, 2024.

R-5. Song, K., Wu, Q., Compaan, A.M., Shen, J., Zhou, C., Chen, M., Sole-Gras, M., Robinson, J.T., Ren, B., Yang, H., Huang, Y., and Yin, J., “Solvent-Rich Pre-Coagulation Bath for Tunable Liquid-State Fusion Enables Robust Two-Step Polymer Embedded Printing,” Advanced Science, Vol. 12(40), p. e08335, 2025.

Laser bioprinting

L-1. Xiong, R., Zhang, Z., Chai, W., Huang, Y., and Chrisey, D.B., “Freeform Drop-on-Demand Laser Printing of 3D Alginate and Cellular Constructs,” Biofabrication, Vol. 7(4), pp. 045011-1-13, 2015. (Featured at IOP medicalphysicsweb)

Inkjet bioprinting

I-1. Xu, C., Chai, W., Huang, Y., and Markwald, R.R., “Scaffold-Free Inkjet Printing of Three-Dimensional Zigzag Cellular Tubes,” Biotechnology and Bioengineering, Vol. 109(12), pp. 3152-3160, 2012.

I-2. Christensen, K., Xu, C., Chai, W., Zhang, Z., Fu, J., and Huang, Y., “Freeform Inkjet Printing of Cellular Structures with Bifurcations,” Biotechnology and Bioengineering, Vol. 112(5), pp. 1047-1055, 2015. (Featured in Wiley’s Biotechnology & Bioengineering)

I-3. Christensen, K., Compaan, A., Chai, W., Xia, G., and Huang, Y., “In Situ Printing-then-Mixing for Biological Structure Fabrication using Intersecting Jets,” ACS Biomaterials Science & Engineering, Vol. 3(12), pp. 3687-3694, 2017.

Extrusion bioprinting

E-1. Jin, Y., Liu, C., Chai, W., Compaan, A., and Huang, Y., “Self-Supporting Nanoclay as Internal Scaffold Material for Direct Printing of Soft Hydrogel Composite Structures in Air,” ACS Applied Materials & Interfaces, Vol. 9(20), pp. 17456-17465, 2017. (Featured by WeChat Polymer-Science)

E-2. Jin, Y., Compaan, A., Chai, W., and Huang, Y., “Functional Nanoclay Suspension for Printing-then-Solidification of Liquid Materials,” ACS Applied Materials & Interfaces, Vol. 9(23), pp. 20057-20066, 2017. (Featured by WeChat Polymer-Science)

E-3. Song, K., Compaan, A.M., Chai, W., and Huang, Y., “Injectable Gelatin Microgel-based Composite Ink for 3D Bioprinting in Air,” ACS Applied Materials & Interfaces, Vol. 12(20), pp. 22453-22466, 2020. (Featured by WeChat Polymer-Science, Polymer.cn)

4D printing and soft robotics

F-1. Jin, Y., Shen, Y., Yin, J., Qian, J., and Huang, Y., “Nanoclay-Based Self-Supporting Responsive Nanocomposite Hydrogels for Printing Applications,” ACS Applied Materials & Interfaces, Vol. 10(12), pp. 10461-10470, 2018.

Process modeling

P-1. Wang, W., Herran, C.L., Coutris, N., Huang, Y., Mironov, V., and Markwald, R., “Methodology for the Evaluation of Double-Layered Microcapsule Formability Zone in Compound Nozzle Jetting Based on Growth Rate Ratio,” ASME Journal of Fluids Engineering, Vol. 135(5), pp. 051203-1-8, 2013.

P-2. Xu, C., Zhang, M., Huang, Y., Ogale, A., Fu, J., and Markwald, R., “Study of Droplet Formation Process during Drop-on-Demand Inkjetting of Living Cell-Laden Bioink,” Langmuir, Vol. 30, pp. 9130-9138, 2014. (Featured by ACS)

P-3. Xu, C., Zhang, Z., Fu, J., and Huang, Y., “Study of Pinch-Off Locations during Drop-on-Demand Inkjet Printing of Viscoelastic Alginate Solutions,” Langmuir, Vol. 33(20), pp. 5037-5045, 2017.